The purpose of brewing is to convert the starch source into a sugary liquid called wort, and to then convert the wort into beer in a fermentation process effected by yeast. Wort is the liquid extracted from the process during the brewing of beer. Wort contains the sugars, the most important being maltose.

At the time, Anne and I lived in a condo. Every couple of months I would remove the cars from the garage and set up my Saturday brewery. My usual production was a 10 gallon brew of a pale ale, or of an IPA. Initially, the finished beer was bottled in 16oz bottles I had collected.

Eventually, I stopped bottling the beer. I stored my new ales in 5 gallon, used soda concentrate kegs. This keg process was of course much easier than bottling, but it led to some pitfalls. The kegs needed to have a small tank of carbon dioxide attached. The carbon dioxide provided re-carbonation, as well as sufficient pressure to gently flow chilled brew out of the attached spigot. This dispensing technique worked wonderfully in my condo man-cave, but it didn't offer a way for me to share some give-away beer with my friends, the way the bottles had. Sure, I would happily give away a keg, but that would mean the recipient would need to set up a carbon dioxide tank and a special refrigerator.

Naturally, this conundrum led to the occasional garage party. Those were fun events, but they were not frequent enough to require me to fire up the occasional weekend brewery. The result was, I ended up with more ale than I could get rid of. My days of brewing slowly dwindled.

During the several years in the condo, I had obtained a license from the City of Medford to brew experimental ales. I had registered a company in Oregon. It was called Medford Heights Brewing, LLC. I have no recollection as to why I went through these steps, other than perhaps to pseudo legitimize my hobby.

Further in the study of the total beer manufacturing process, I enrolled in an on-line brewing certification course offered by U.C. Davis, in California. The course took several months to complete. The final exam required me to drive to Davis to sit for the test. The exam was not easy, but I had passed.

My brewing hardware has long been stored away. I have reflected with fondness on the process of converting starches into a wonderfully tasting ale. An anchor has kept me from going to the shed and digging everything out. But then, a serendipitous thing happened. I found out that my dentist, Scott Brodie, was also a skilled brewer. Well, as sometimes fortunate things come about, I received an invitation from Scott to join he and his brewing partner on their next brewing day.

On Thursday afternoon, August 8th, I joined Scott and his partner, Jessie, at the Brodie family Brewhaus in Jacksonville, OR. I arrived at the scheduled time of 2pm. Scott and Jessie were already hard at work preparing things in the brewery for the afternoon's work.

Scott has dedicated a small outbuilding on their Jacksonville stead to his brewing hobby. Unlike with my scabbed together pieces of brewing hardware, Scott has made a small investment in setting up his brewpub with some nicely integrated equipment.

The most critical aspect of the brewing process is that of controlling temperatures. Scott had built The Electric Brewery. The Electric Brewery is a 240volt, 30amp, kit which controls the temperatures in both the hot liquor tank and the boiling tank. This hardware allows one to set both temperature as well as heating times on those two containers. Alarms sound when the times have completed. Alarms can also alert you if there is a problem in the process. The beauty of The Electric Brewery control is that it is electric. There is no propane heating source to fuss with. It is “set it and forget it”.

Today's brewing schedule is to brew Wet Hop Pale Ale. What is a wet hop beer? Hops are the seed cones of the plant species Humulus lupulus. They are actually the very delicate flowers of the plant. They don’t survive long after being cut, which is why almost all hops are dried immediately after harvest. The cones are picked from the bine and spread out over kiln room floors. There they are hot air, or kiln dried. Kiln drying preserves the valuable oils and resins that add so much savor and tang to beer. The hops can then be pressed into pellets, or left as cones. Most hops used by brewers are in this dried or pellet form.

Wet hops, the freshly picked cones, have a different taste than kiln-dried hops. The base notes are similar—floral, bitter, spicy, tangy—but there is a less full-throttle intensity, and the fresh hops add a vibrancy, a fineness, a definition, and a chlorophyll-driven energy that you don’t get in standard-hopped beers.

Jessie brought with him today three bags of freshly picked hops. He grew the hops on his own property. The hop plant, Humulus, is of the family Cannabaceae. This family also contains the hemp plants, which grow abundantly in the greater Medford area. The hops are different varietals: Zeus, Willamette, and Crystal. We spent a few minutes picking the cones from the bines of each variety.

Because the hop cones are not dried they contain the extra weight of the flower's water. Scott spent a few minutes converting the wet cone weights into their equivalent dried hop values. The conversion is that a fresh cone weights five times more than a dried one. Knowing how much of each variety he had, Scott determined what he needed to match the recipe's requirement.

The most important ingredient in making beer is the grain, the source of starch. Scott and Jessie are using three varieties of malted barley in this brew. They are American two-row,

Cara-Pils, and Munich. The two-row malt is the base malt for all-grain recipes. This recipe calls for 33 pounds of the two-row malt. The Cara-Pils malt will add an unfermentable sugar to the finished brew. This will lead to a sweet and higher final gravity to the ale. The Munich malt has been kiln-dried at a higher temperature than either the two-row or the Cara-Pils. The higher kiln temperature creates a darker malt and that produces richer flavors. The Wet Hop Pale Ale recipe calls for two pounds of each of the specialty malts.

Scott weighed out the called for amounts of grain. Jessie used a portable drill to spin the gears of a grain mill. The malted grain needs to be broken open for the mashing process to be able to extract the enzymes which will convert the grain's starch into fermentable sugars. The resulting grits need to be of a size which will permit efficient extraction, but not too small that they block the final washing, or sparging of the mashed grain. The optimal compromised crush size sets the mill's gap at 0.045 inch. Partly through the crushing task the lithium battery on the drill suddenly died. There was a pause in the process while Jessie located a second battery for the drill.

After all of the ingredients are collected, the next step is known as mashing. This prepares the wort. Hot water is mixed with crushed malt, known as grist, in a mash tun.The mashing process takes usually one hour. The Electric Brewery has heated the water in the hot liquor tun to an optimal mash temperature of 152F. Several gallons of the hot water are pumped into the neighboring mash tun. The grist is then slowly added to the water and gently stirred.

The Electric Brewery has a control for turning on and off a pump which will circulate the wort through a coil of copper pipe immersed inside the hot liquor tun. This will maintain the wort in the mash tun at the desired temperature.

During the mash the starches are converted to sugars. After the one hour mash time, the sweet wort is then drained off the grains. A second pump slowly removes the wort and transfers it to a boiling tun. During this transfer the grains are washed in a process known as sparging. Water from the hot liquor tun has been raised to 172F and it is pumped over the mash. This washing allows for the collection of as much of the fermentable sugars from the grains as possible.

The traditional process for wort separation is lautering, in which the grain bed itself serves as the filter medium. During the mashout the temperature of the mash is increased to accomplish two things: First this temperature stops the action of the enzymes that were activated in the mash, and thus stops the conversion of starch to sugar. And second, heating the mash thins it out so that it will flow and drain better.

The ability to use the spent grain bed as a filter during the lautering is one of the reasons the grist mill grinding setting is so important. Setting the crush size to very small would allow a more efficient extraction during the mash, but it would then form a spent grain bed which would be too compact to permit lautering. The wort would not drain. The sparge water pump and the wort transfer pump are both carefully set to allow a very slow filtering of the mash.

Boiling the wort serves several purposes and it usually lasts for an hour or more. The first thing boiling does is it kills any wild yeasts and bacteria. Their presence could spoil any final result. The initial addition of hops is done at the start of the boil. These are called the bittering hops. This long boil of the hops extracts resins which impart the distinct bitter hop taste.

Boiling the wort ensures the deactivation of the starch-to-sugar converting enzymes. If this were not done the resulting ale would have a dry taste, with less full-mouth flavor. Lastly, the sparge is boiled to reduce the volume of liquid. Knowing how much the starting volume is, and the evaporation rate of the boiling tun permits Scott to determine and set what the starting specific gravity of the pre-fermented wort is, i.e., how much sugar is in the final volume of liquid.

Flavoring hops are added to the boil at about 15 minutes before the end. The finishing hops are added at the end of the boil. Doing this extracts the hop oils, which add flavor but also the desired hop aroma. In general, hops provide the most flavoring when boiled for approximately 15 minutes, and the most aroma when not boiled at all.

Following the boil, the wort is cooled quickly to about 70F. It is then agitated to add oxygen back into the liquid. Sufficient oxygen in the wort is important for yeast health and growth during fermentation. Without oxygen the added yeast will not be able to multiply, and it is the vigorous yeast growth which ensures a complete fermentation of all available sugars.

While boiling was being done, Scott and Jessie readied the fermenting vessel for this new brew. The SS Brewing Technologies fermenter held 17 gallons of the last ale they had made. Scott drained the trub from the bottom of the fermenter, and Jessie then transferred the contents into 5-gallon kegs.

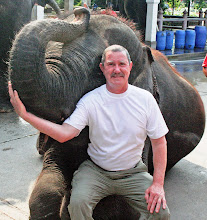

The day had reached five o'clock. Scott, his wife, Kyleen, Jessie and friends were relaxing outside of the brewhaus during the long boil period. I had had the opportunity to sit through, and participate a little in the making of an ale using modern home-brewing equipment. I will await the call for a chance to once again visit the Brodie Brewhaus to sample the end result of this Wet Hop Pale Ale brew day. Thank you Scott, and Jessie, for sharing this experience.